How to Enhance Flexible Screw Conveyor PerformanceHow to Enhance Flexible Screw Conveyor Performance

A properly configured flexible screw conveyor can transform your material handling process.

February 24, 2025

Flexible screw conveyors are widely used in manufacturing due to their simple yet efficient design. Unlike other conveyor systems, these conveyors rely on a single moving component—the screw (also called an auger)—to transport materials. The combination of reliability, cost-effectiveness, and adaptability makes them a popular choice across industries. However, maximizing their efficiency requires careful consideration of key design and operational factors.

In today's competitive manufacturing landscape, optimizing productivity and operational efficiency is paramount. Flexible screw conveyors offer an ideal solution by enabling seamless material handling across a variety of industries, including food processing, pharmaceuticals, chemicals, and construction. Here we will explore the key features, advantages, and design considerations of flexible screw conveyors, helping you make an informed decision to maximize productivity and minimize costs.

Understanding Flexible Screw Conveyors

Flexible screw conveyors utilize a simple yet highly effective mechanism to move bulk materials. They consist of a rotating helical screw inside a fixed tube, driven by an electric motor. As the screw rotates, it pulls material through the tube, effectively conveying it from one point to another. The flexibility of the screw and tube design allows for installations in tight spaces, around obstacles, and at various angles, making them extremely versatile.

One of the key advantages of flexible screw conveyors is their minimalistic design, which reduces maintenance and operational costs. With only one moving part—the screw—there are fewer points of failure compared to more complex conveyor systems. Additionally, the enclosed design ensures dust-tight operation, maintaining a clean work environment and preventing contamination.

The simplicity of the design, however, does not compromise its performance. Flexible screw conveyors are capable of transporting a wide range of materials, including powders, granules, pellets, and flakes, making them ideal for applications in multiple industries. A flexible screw conveyor consists of three main components:

1. Helicoid Screw: A rotating auger inside the fixed tube

2. Tubular Housing: Guides material along the transport path

3. Electric Motor: Powers the screw to move materials

This design allows for simple operation and minimal maintenance.

Key Specifications and Capabilities

Flexible screw conveyors are highly adaptable, capable of handling diverse materials and operating under varied conditions. Understanding their specifications and capabilities is paramount for selecting the right system for your application.

Screw Diameters and Tube Sizes: Available in diameters ranging from 2.5 to 8 in., flexible screw conveyors can be tailored to specific throughput requirements.

Conveying Distance and Angles: These conveyors can efficiently move materials over horizontal distances of up to 80 ft and at inclines of up to 60˚. Configurations with a gradual bend or vertical lifts can also be achieved, offering exceptional installation flexibility.

Capacity and Speed: An 8-in.-diam screw operating at 360 RPM can convey up to 1,800 cu ft/hr. The flow rate can be adjusted by varying the screw’s rotation speed or altering the auger’s pitch and diameter.

Material Compatibility and Flow Characteristics: Flexible screw conveyors can handle a wide range of materials, from free-flowing powders like flour and sugar to more challenging substances such as titanium dioxide (TiO2) and zinc oxide. Understanding the material’s bulk density, particle size, moisture content, fat content and flow properties is essential for selecting the optimal conveyor configuration.

By carefully matching system specifications to your specific application requirements, you can maximize productivity and minimize operational costs.

Auger styles: (left) flat, beveled, square, and round wires (Hapman)

Selecting the Right Auger for Your Material

Choosing the right auger is critical for ensuring efficient material handling while minimizing wear, energy consumption, and product degradation. Each auger type offers unique advantages, making it essential to match the auger design to the specific material being conveyed.

1. Flat Wire Auger

Best for light powders, fine granules, and other low-density materials

Advantages: Delivers consistent forward thrust with minimal outward force against the tube wall, reducing friction and wear. Ideal for handling fragile products without breakage.

Considerations: Not suitable for heavy, abrasive materials as the flat surface may increase drag and energy consumption or could stretch the auger.

2. Beveled or Square Bar Auger

Best for difficult-to-handle materials, such as food products, pharmaceuticals, and certain chemicals

Advantages: Minimizes product degradation by maintaining a low impact conveying action. Its unique design allows smooth material flow with reduced friction. Additionally, it can help reduce motor amperage when conveying hygroscopic materials.

Considerations: Operates at lower maximum RPMs (450 or less) to ensure gentle product movement. Requires straight installation for optimal performance.

3. Round Wire Auger

Best for heavy, abrasive, or high-density materials like salt, sand, metal powders, and minerals

Advantages: Offers superior strength and flexibility, enabling efficient movement of dense and abrasive substances. The round wire shape minimizes surface contact, reducing friction and wear.

Considerations: Generates higher slippage and outward force, which may affect flow consistency in certain materials.

4. Centercore Auger

Best for highly aerated, fluid-like, or cohesive materials prone to clogging or bridging

Advantages: Reduces the material load by restricting the fill area. It also prevents fallback and fluidization, maintaining consistent flow rates.

Considerations: Decreases overall capacity but enhances flow consistency and operational stability

Optimizing Conveyor Performance

Several factors influence flow rate and overall conveyor efficiency:

* Auger type and rotation speed

* Material characteristics (density, abrasiveness, moisture content)

* Tube configuration and incline angle

* Hopper size and loading method

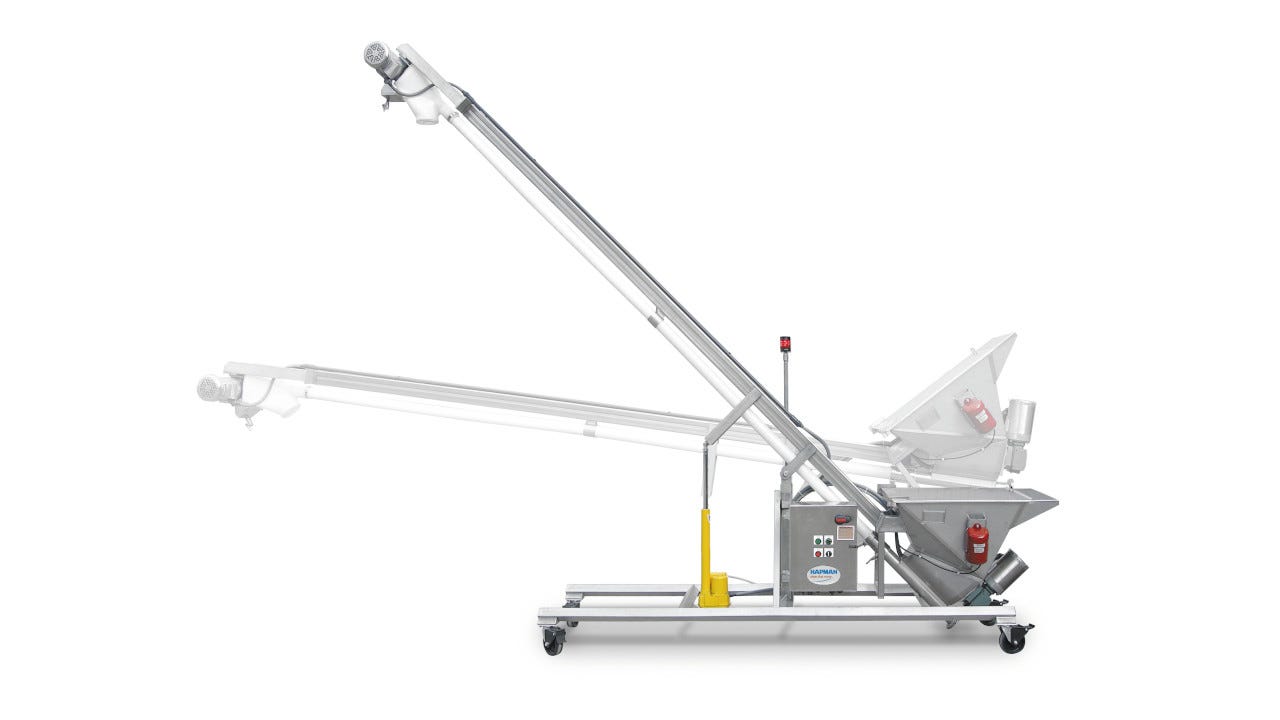

Hapman's Helix HiLo conveyor allows operators to lower the conveyor for complete cleaning and auger removal (Hapman).

Best Practices for Performance Optimization

* Where possible, maintain an incline angle of 45˚ or lower to reduce backflow risks.

* Match the auger type to the material to minimize wear and maximize efficiency.

* Use sensors to detect material presence and prevent running empty, which can cause excessive vibration and accelerated wear

Advantages & Considerations

Advantages of Flexible Screw Conveyors

* Versatile for various materials (powders, granules, flakes, pellets)

* Compact design saves floor space.

* Low maintenance and easy to clean

* Can transport both horizontally and at an incline

* Customizable configurations for different applications.

Potential Limitations

* Material residue can remain in the casing, requiring periodic cleanout.

* Maximum transport limitations: 80 ft (horizontal), 60˚ (inclined)

* Different augers may be needed when handling multiple material types.

Cleaning & Maintenance Best Practices

Keeping your conveyor clean is crucial for preventing contamination and maintaining efficiency.

Cleaning Options

1. Reversing the Screw: Evacuates residual material from the tube

2. Air, Water, or Solvent Rinse: Cleans the system without disassembly

3. Hi/Lo Conveyor System: Allows operators to lower the conveyor for complete cleaning and auger removal

Modes of Operation

1. Batch Operation

Best for applications requiring precise measurements

Minimizes leftover product in the conveyor

2. Intermittent Operation

Ideal for processes requiring start-stop functionality

Heavy materials may require modifications for easier start-up

3. Continuous Operation

Suitable for long production runs

Requires optimized design for sustained performance

Hapman’s 300 Series Helix flexible screw conveyor with polyurethane hopper and flat wire auger, conveys plastic pellets 28 ft into a form-fill-seal solution (Hapman).

Conclusion

Flexible screw conveyors provide a cost-effective, efficient, and versatile solution for bulk material handling across a wide range of applications and industries. Their simple yet robust design minimizes maintenance requirements while maximizing productivity and operational efficiency.

By selecting the right auger type, optimizing system specifications, and implementing proper operational and maintenance practices, manufacturers can significantly enhance conveyor performance. This not only maximizes productivity but also reduces operational costs and extends equipment lifespan.

Whether you are handling light powders, abrasive minerals, or fragile food products, a properly configured flexible screw conveyor can transform your material handling process.

Mike Zeluff has nearly 30 years of experience as a technical product manager at Hapman. He has extensive knowledge of material testing and flow dynamics, ensuring optimal bulk material handling solutions for various industries. For more information, call 800-427-6260, email [email protected], or visit www.hapman.com.

About the Author

You May Also Like